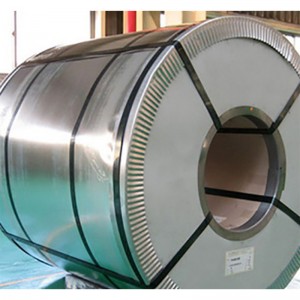

321 tubus coil immaculatus ferro coil tubus pretium coil

Descriptio

321 ferro intemerata coilis titanium stabilitur austenitico intemerato coil ferro cum bono generali corrosione resistente.Praeclarum resistentiam habet ad corrosionem intergranulare exposita temperaturis in chromium carbidi praecipitationis 800 - 1500° F (427 - 816°C).stannum oxidationis resistit usque ad 1500°F (816°C) et altius serpere et accentus rupturae proprietates quam admixtiones 304 et 304L habet.Etiam durities pollet bonam frigiditatem.

Admisceri 321H (UNS S 32109) coil chalybeis immaculatus est superior carbonis (0.04 - 0.10) versio stannum.Enucleata est ad auctam resistentiam subrepentes et ad superiores vires temperaturas supra 1000oF (537°C).Pleraque materia carbonis contentum coil dat duplicem certificationem.

Admisce 321 intemerata cochleam ferro non calore curationis indurari, nisi frigore operante.Facillime iuncta et discursum esse potest per normas officinas fabricandi exercitia.

An ISO 9001:2008 Certificata Societas, Sabaudiae limbis Inc., princeps est Stockholder, Supplier et Exporter ASTM A240 321 Steel Coil.321 intemerata gyro ferro incisa tuis specificationibus et instrumentis molendini instrumentis plenis instructum refert.Consuetudo longitudo et latitudo usque ad 2000 mm praesto effici possunt.Exportatio nostra Proprium est!et plures invenire difficiles gradus ac vel non signa magnitudinis invenire possumus ut peculiaribus nostris clientibus requisitis.Omnes ASTM SS 321 Ferro Coil secari possunt ad magnitudinem, ope nostrae amplae peritiae in ferro Coil producto dispensando.

Prosapia nostra ASTM A240 321 Steel Coil includit crassitudinem 6mm usque ad 80mm cum latitudine 1250mm, 1500mm, 2000mm.

Praesto Aliae Gradus

Possibile est alternative gradus ad 321 intemeratam ensem anguem.

| LAT-standard | LAT-standard | SAE gradus | UNS |

| 1.4109 | X65CrMo14 | 440A | S44002 |

| 1.4112 | X90CrMoV18 | 440B | S44003 |

| 1.4125 | X105CrMo17 | 440C | S44004 |

| 440F | S44020 | ||

| 1.4016 | X6Cr17 | 430 | S43000 |

| 1.4408 | GX 6 CrNiMo 18-10 | 316 | S31600 |

| 1.4512 | X6CrTi12 | 409 | S40900 |

| 410 | S41000 | ||

| 1.4310 | X10CrNi18-8 | 301 | S30100 |

| 1.4318 | X2CrNiN18-7 | 301LN | |

| 1.4307 | X2CrNi18-9 | 304L | S3043 |

| 1.4306 | X2CrNi19-11 | 304L | S30403 |

| 1.4311 | X2CrNiN18-10 | 304LN | S30453 |

| 1.4301 | X5CrNi18-10 | 304 | S30400 |

| 1.4948 | X6CrNi18-11 | 304H | S30409 |

| 1.4303 | X5CrNi18-12 | 305 | S30500 |

| X5CrNi30-9 | 312 | ||

| 1.4841 | X22CrNi2520 | 310 | S31000 |

| 1.4845 | X 5 CrNi 2520 | 310S | S31008 |

| 1.4541 | X6CrNiTi18-10 | 321 | S32100 |

| 1.4878 | X12CrNiTi18-9 | 321H | S32109 |

| 1.4404 | X2CrNiMo17-12-2 | 316L | S31603 |

| 1.4401 | X5CrNiMo17-12-2 | 316 | S31600 |

| 1.4406 | X2CrNiMoN17-12-2 | 316LN | S31653 |

| 1.4432 | X2CrNiMo17-12-3 | 316L | S31603 |

| 1.4435 | X2CrNiMo18-14-3 | 316L | S31603 |

| 1.4436 | X3CrNiMo17-13-3 | 316 | S31600 |

| 1.4571 | X6CrNiMoTi17-12-2 | 316Ti | S31635 |

| 1.4429 | X2CrNiMoN17-13-3 | 316LN | S31653 |

| 1.4438 | X2CrNiMo18-15-4 | 317L | S31703 |

| 1.4362 | X2CrNi23-4 | 2304 | S32304 |

| 1.4462 | X2CrNiMoN22-5-3 | 2205 | S31803/S32205 |

| 1.4501 | X2CrNiMoCuWN25-7-4 | J405 | S32760 |

| 1.4539 | X1NiCrMoCu25-20-5 | 904L | N08904 |

| 1.4529 | X1NiCrMoCuN25-20-7 | N08926 | |

| 1.4547 | X1CrNiMoCuN20-18-7 | 254SMO | S31254 |